Known as a leader in innovation

Welding

High efficient MIG welding with TIG quality

The Cutting-Edge Solution for Modern Welding

In the realm of welding technology, OTC Daihen’s Welbee welding machine has established itself as a game-changer, offering precision, efficiency, and reliability. Renowned for its advanced features and robust performance, the OTC Welbee series caters to industries demanding high-quality welding solutions.

What is OTC Welbee?

OTC Welbee falls under the category of over-the-counter medications, meaning these products can be purchased directly without a doctor’s prescription. The range typically includes medications, health supplements, and personal care products that are safe when used according to the instructions provided on the packaging.

Focused on improving public access to healthcare, OTC Welbee makes its products widely available through pharmacies, convenience stores, and online platforms.

OTC Welbee offers a variety of products across multiple categories, including:

Welding of thin material at high speeds without material distortion

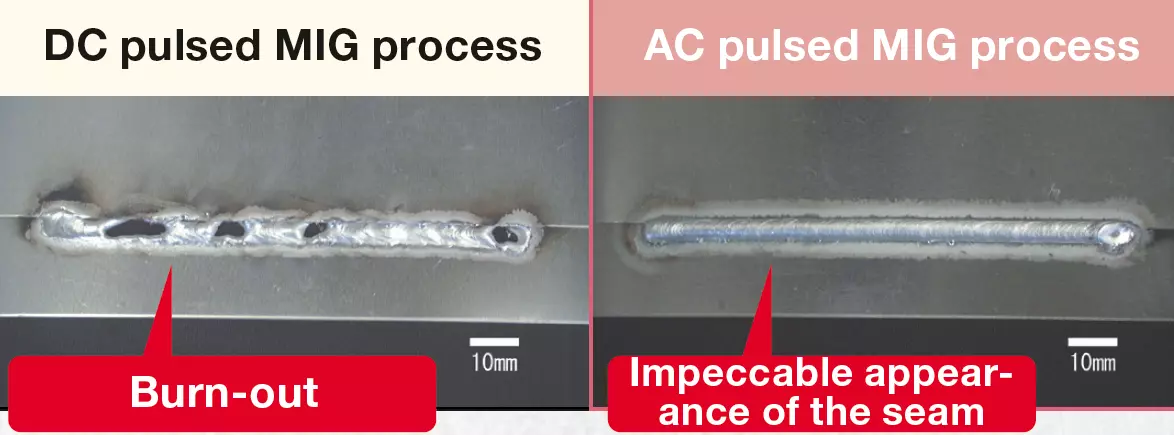

AC/MIG welding is a highly effective welding process that combines two important features: a higher melting rate and an improved penetration control. The increased melting rate at constant current input lowers the heat input into the workpiece. These features make it an ideal choice for welding thin metal sheets up to 0.6 mm in thickness without sacrificing the quality of the weld. AC/MIG welding is applicable for a wide range of materials, including steel, stainless steel, and aluminum.

Improved gab bridging

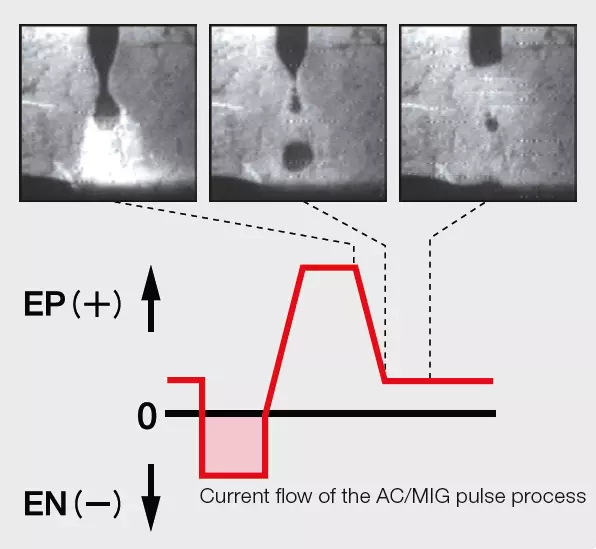

One notable advantage of AC/MIG welding is the flexibility it offers with regard to electrode polarity. In addition to the commonly used positive electrode, known as direct current electrode positive (DCEP), AC/MIG welding allows for the utilization of a negative electrode, referred to as direct current electrode negative (DCEN). This unique feature forms the basis of the welding process, as it involves the alternating current (AC) between DCEP and DCEN.

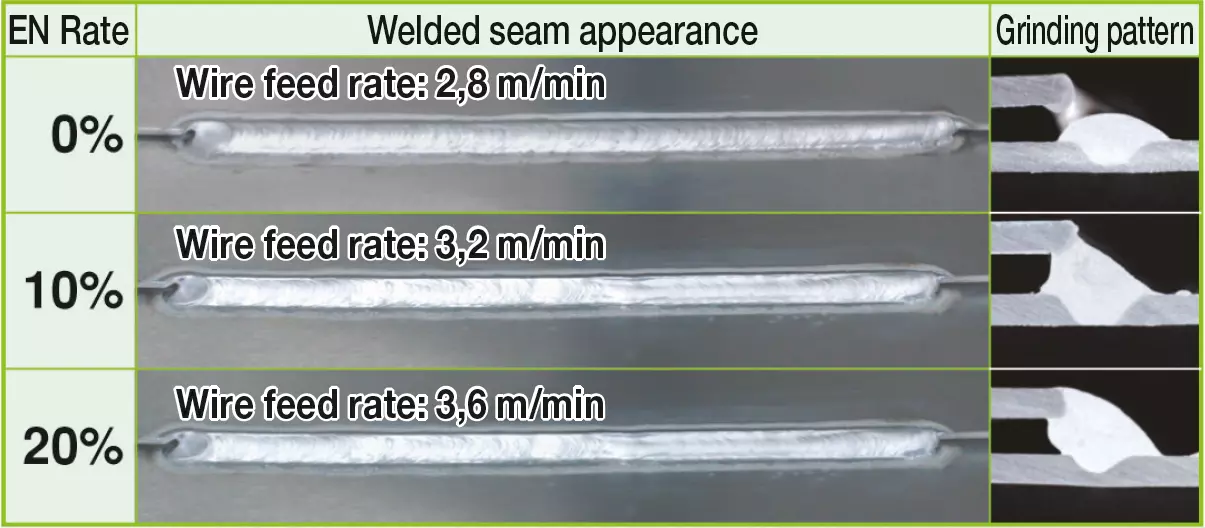

An important aspect influenced by the welding parameters is the EN Ratio, which refers to the proportion of time allocated to the DCEN polarity. By increasing the EN Ratio, there is a corresponding increase in the wire feed rate. Consequently, the higher wire feed rate leads to a greater deposition rate of the welding wire onto the workpiece. This enhanced deposition rate results in an improved capability to bridge gaps between materials during the welding process.

By adjusting the EN Ratio and increasing the wire feed rate, the deposition rate of the welding wire can be heightened, resulting in improved gap bridging capabilities.

Less welding fumes and oxid layers

AC/MIG welding also offers the benefit of producing less welding fumes and oxide layers. This results in a cleaner weld surface compared to other welding methods. The low temperature required for drop transfer in AC/MIG welding reduces the production of welding fumes. Consequently, there are fewer burn marks and less fume generated during the process. This contributes to a cleaner and visually appealing weld finish.

Fitting your needs

Plasma welding machine Depending on the original torch structure Correspondent to stable and wide current range!

PT Sinar Unggul Pratama

Bintang Industrial Park aII Lot D1 619-620

Tanjung Uncang, Batam-Indonesia 29424