🏠︎ » Cutting » Hypertherm » XPR Plasma

Exploring HYPERTHERM XPR Plasma

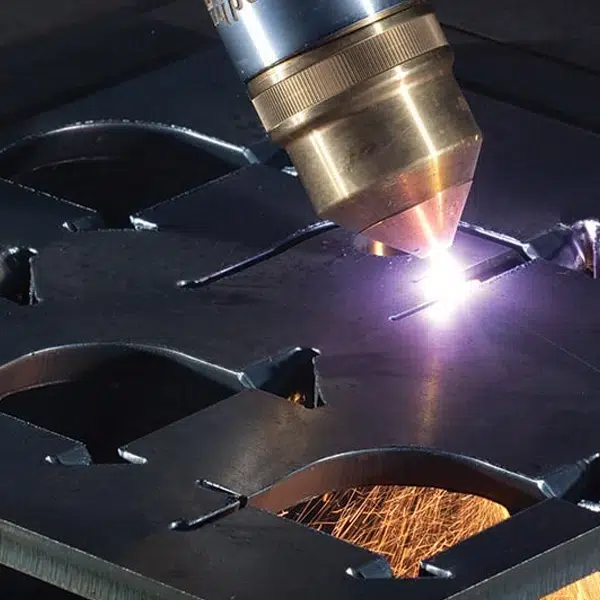

HYPERTHERM XPR Plasma is one of the most advanced metal cutting technologies available today. Developed by Hypertherm, a company renowned for its innovations in metal cutting solutions, the XPR series delivers unmatched efficiency, precision, and ease of use. It is designed to meet the demands of modern industries requiring high-quality results and optimized workflows.

High Precision

The XPR Plasma system provides exceptional cutting accuracy, making it ideal for applications that demand intricate details. With High Definition Plasma (HDi) technology, it ensures superior cut quality on both thin and thick materials.

Operational Efficiency

Equipped with features like True Hole technology and Advanced Arc Stability, the XPR Plasma system significantly reduces gas consumption and extends the lifespan of consumables such as nozzles and electrodes.

User-Friendly Design

The system features an intuitive interface, and its SmartSense technology automatically adjusts gas pressure based on the material type and thickness. This minimizes manual adjustments and enhances overall productivity.

Enhanced Durability

Built with high-quality components, the XPR Plasma system is highly durable and designed to perform even in demanding industrial environments. This makes it a reliable and cost-effective investment for long-term use.

Material Versatility

The XPR Plasma system is compatible with various materials, including carbon steel, stainless steel, and aluminum. It can handle a wide range of thicknesses, making it suitable for diverse industrial applications.

Industrial Applications

The HYPERTHERM XPR Plasma system has been adopted across numerous industries for cutting metal. Key applications include:

Automotive Manufacturing

Used to create precision components such as frames, panels, and engine parts.

Construction

Ideal for fabricating building structures, bridges, and other infrastructure.

Shipbuilding

Essential for cutting thick steel plates used in ship construction.

Energy Sector

Used in the production and maintenance of energy equipment, including turbines and pipelines.

Advantages for Modern Industry

The HYPERTHERM XPR Plasma system is a game-changer for industries looking to enhance productivity and quality. With advanced features and cutting-edge technologies, it offers:

HYPERTHERM XPR Plasma represents the pinnacle of plasma cutting technology, offering unparalleled performance, efficiency, and versatility. By investing in this system, industries can meet market demands more effectively while reducing operational costs and boosting productivity.

For businesses seeking a reliable, high-performance cutting solution, HYPERTHERM XPR Plasma is the ultimate choice.

Fitting your needs

XPR300™ (200V – 240V), (380V – 600V), XPR170™ (200V – 240V), (380V – 600V)

The XPR170® mechanized plasma cutting system delivers next generation X-Definition® processes from very thin up to mid-range thicknesses.

Cut faster and use fewer consumables with the XPR300® mechanized plasma cutting system. With unmatched X-Definition® cut quality on mild steel, stainless steel and aluminum, the XPR300 increases cut speed, dramatically improves productivity and slashes operating costs.

The XPR460 delivers the most consistent cut quality, thicker cutting capability, and faster cutting speeds in its class—increasing productivity and lowering operating costs.

PT Sinar Unggul Pratama

Bintang Industrial Park aII Lot D1 619-620

Tanjung Uncang, Batam-Indonesia 29424