Fits your needs

OTC Contact Tip | MAG-Tip (40L, 45L)

Description

Technical specification

OTC Contact Tip | MAG-Tip (40L, 45L)

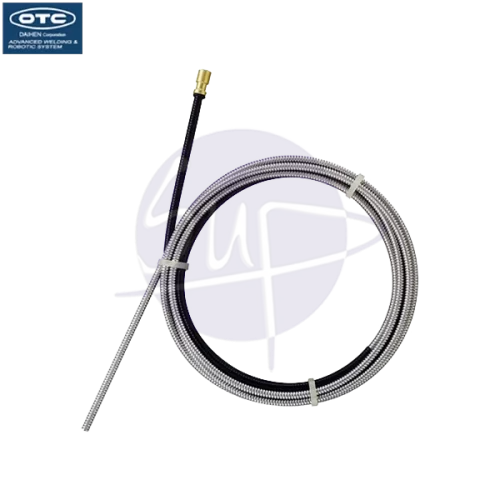

The OTC MAG‑Tip (40L, 45L) contact tip is engineered for heavy-duty MAG welding applications requiring high current, such as thick steel or stainless steel fabrication. Compared to standard T‑Tips, MAG‑Tips have increased mass and enhanced thermal capacity, delivering more stable arc characteristics during demanding welding tasks.

Feature & Application:

-

- MAG-tip has a further larger mass and largely-enhanced thermal capacity compared to T-tip.

- MAG welding with high current or heavy welding.

- Stainless steel MIG welding with high current.

Key Features & Applications

-

- Enhanced Thermal Capacity

The larger body mass of the MAG‑Tip allows it to absorb and dissipate heat more effectively, preventing overheating during prolonged welding runs and maintaining consistent tip life - Stable High-Current Welding

Optimized for high-current MAG processes, these tips deliver a stable arc and ensure reliable wire feeding, resulting in uniform weld deposition and reduced spatter on steel and stainless sheets - Air-Cooled Design

Available in both 40 mm and 45 mm lengths, the air-cooled tip fits OTC’s Blue Torch II and Black Torch MIG torches. The tip supports wire diameters ranging from 0.8 to 1.6 mm, matching heavy welding needs - Durable Construction

Manufactured from high-grade copper alloys with precision-drilled tip holes, MAG‑Tips ensure consistent electrical contact and minimal resistance—delivering improved welding performance and lifespan

- Enhanced Thermal Capacity

The OTC MAG‑Tip (40L/45L) is a premium contact tip solution for industrial MAG welding requiring high current and consistent performance. Its enhanced thermal mass, precision construction, and durable materials ensure stable arcs, efficient heat management, and longer tip life. Ideal for professional fabricators working with thick materials or extended weld sequences. For wire size specifics, pricing, or purchasing in Batam, just let me know!

SPECIFICATION:

|

Shape |

Name | Wire | Part# | Reference |

|

MAG/MIG tip (45L) | 1.2 | U4167H12 |

BLUE TORCH II |

|

1.4 |

U4167H11 |

Discover more

The LORCH X 350 PST is a robust MMA welding system with automatic polarity switching, ControlPro digital interface, and MicorBoost technology—ideal for tough construction and pipeline jobs.

Lorch V 50 AC/DC – 500 A heavy-duty TIG welder with pulse up to 20 kHz, SmartBase controls, and robust housing — ideal for shipyards and fabrication in Batam.

Lorch V40 AC/DC TIG welder blends 400 A heavy-duty welding with pulse up to 20 kHz, SmartBase control, and robust housing—ideal for shipyards and fabrication in Batam.

LORCH MicorMIG Mobile 350 – pulse arc welding with MicorBoost reduces spatter and rework. Upgradeable, reliable, and efficient—ideal for fabrication, shipbuilding, and workshop use in Batam.

LORCH MicorMIG Mobile 300 – low‑spatter pulse arc welding with MicorBoost & NFC upgrades. Ideal for Batam’s fabrication, shipbuilding, and workshop welding.

Lorch MicorMIG Pulse 500 – high-power, low-spatter MIG/MAG pulse welding with MicorBoost, EN 1090 compliance & NFC upgradeability. Ideal for Batam’s heavy industry.

Lorch MicorMIG Pulse 400 – high-performance MIG/MAG pulse welding with MicorBoost, EN 1090 compliance, and NFC upgradability. Ideal for shipbuilding, fabrication, and workshop applications in Batam.

Lorch MicorMIG Pulse 350 – pulse arc welding with MicorBoost reduces spatter and rework. Upgradeable, reliable, and efficient—ideal for fabrication, shipbuilding, and workshop use in Batam.

Lorch MicorMIG 500 – Top-tier MIG/MAG welder for industrial-grade projects in Batam, with German MicorBoost technology and full-process capability.

Lorch MicorMIG 350 – Premium German-made MIG/MAG welder with MicorBoost and SpeedArc, ideal for industrial welding in Batam’s fabrication and shipbuilding sectors.

Lorch MicorMIG 400 – High-power industrial MIG/MAG welder with MicorBoost and SpeedArc, ideal for fabrication, shipbuilding, and manufacturing in Batam.

Lorch MicorMIG 300 – German-engineered MIG/MAG welder with MicorBoost technology, perfect for industrial applications and mobile welding jobs in Batam.

The Lorch S5 SpeedPulse XT delivers top-tier MIG/MAG pulse welding with intelligent arc control—ideal for heavy-duty fabrication and shipyard welding in Batam.

Lightweight, ergonomic MIG/MAG torch with up to 550 A duty cycle. MB EVO PRO offers top comfort, flexibility, and performance for industrial welding.

4 kg payload collaborative welding cobot, 37 kg lightweight, ISO‑compliant safety, high trajectory accuracy—perfect for compact, flexible welding.

Digital air plasma cutter with powerful 60A output, suitable for cutting thick steel plates with precision and stability on-site.

Digital air plasma cutter with robust performance, ideal for on-site metal cutting tasks.

Digital AC/DC TIG welder with pulse control, ideal for aluminum, stainless, and mild steel.

Ensures precise tungsten electrode alignment for stable arc performance in WP17/18/26 TIG torches.

Ensures precise tungsten electrode grip for stable arc performance in WP17/18/26 TIG torches.

Carbon gouging rods deliver precise metal removal with excellent arc stability for heavy-duty applications.

Carbon gouging rods deliver precise metal removal with excellent arc stability for heavy-duty applications.

Torch Nozzle ensures optimal performance and safety in high-amperage welding applications.

MIG Torch Insulator ensures optimal performance and safety in high-amperage welding applications.

Available in 200A to 500A models, offers durability and precision for various welding applications.

500 A MAG/MIG synergic inverter welder, water‑cooled with trolley, 100% duty cycle—built for heavy-duty industrial welding operations.

FD‑V25 (S2) 6‑axis robot, 25 kg payload, 1.710 mm reach, slim design & fast cycle time—ideal for arc welding and material handling.

7-axis long-reach robot, 6 kg payload, 2 006 mm reach, ±0.08 mm repeatability—ideal for welding & handling in tight spaces.

is a 6‑axis industrial robot with 80 kg payload and 2.5 m reach, slim profile, built‑in cabling—perfect for material handling and welding support.

bench-type electrode oven, 450 mm rod capacity, 50–300 °C analog control, stainless steel interior, durable & user-friendly.

Floor-type electrode oven, 300 kg capacity, 30–400 °C range, analog thermostat, 75 mm ceramic insulation—efficient & reliable.

Heavy-duty rotating earth clamp, 1000–1200 A, compact 220×230×110 mm, 5.8 kg – reliable grounding for welding.

OEM contact tip holders for OTC MIG torches (WT2000–5000), ensures secure electrical flow & precise wire feeding.

Ceramic insulators for 350 A & 500 A OTC MIG torches. Ensure proper shielding gas flow, tip alignment, and electrical isolation.

350 A ceramic gas diffuser, ensures smooth laminar gas flow and prevents arc spatter at tip—durable precision for tight welding.

OTC Long‑Tip contact tip: .030–.062″ MIG tip, 45 mm long M6 thread, ideal for narrow grooves and deep access—durable and precision‑machined.

Standard Tip for CO2/MAG welding (normally-installed tip for Blue Torch Ⅱ)

Simple and excellent Durable structure … m Excellent operability as it is lightweight

DC welding machine with digital control, up to 630A current, and gouging function, ideal for welding low-carbon steel to copper alloys.

DC welding machine with IGBT inverter control, up to 400A current, ideal for welding with cellulose-coated electrodes in all positions.

AC/DC TIG welding machines with thyristor control, 7 welding modes, and up to 300A output, perfect for aluminum and various metal welding.

DC TIG welding machine with pulsed TIG and Stick modes, up to 315A current, perfect for mild steel, stainless steel, and nickel alloys.

Digital inverter TIG welding machine with automatic synergy function, up to 300A current, compact design, ideal for mild steel, stainless steel, and nickel alloys.

AC/DC TIG welding machine with hybrid AC+DC mode, up to 350A current, AC frequency up to 500Hz, perfect for aluminum and thin to thick steel plates.

Compact CO₂/MAG/MIG welding machine with up to 210A output, ideal for light industry and automotive repair applications.

Versatile CO₂/MAG welding machine with up to 600A output, ideal for steel structures, bridges, and shipbuilding.

Digital inverter welding machine with up to 400A output, ideal for automated and robotic applications across various materials.

Digital inverter welding machine with up to 300A output, ideal for MIG/MAG and TIG applications across various materials.

Digital inverter welding machine with up to 300A output, ideal for MIG/MAG and TIG welding across various materials.

Digital inverter CO₂/MAG welders up to 500A, featuring stainless steel mode and storage for 30 welding conditions for high efficiency.

350A/500A digital inverter welders with optimal current control, high arc stability, and low spatter for high-quality welding results.

350A digital inverter welder featuring low spatter mode, optimal current control, and high arc stability for superior welding quality.

500A digital inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

400A AC/DC inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

500A CO₂/MAG welding torch featuring ergonomic design, air cooling, and flexible cable for precise welding and maximum comfort.

500A MIG welder featuring double pulse technology, ideal for precise welding of aluminum, steel, and various metals.

300A inverter TIG welder featuring IGBT technology, compact design, high efficiency, and precise control for quality welds

120A inverter welder, lightweight and portable, ideal for DIY projects and light industrial applications with high efficiency.

Bench-type electrode oven with digital temperature control, 30°C–400°C range, 155 kg capacity (450 mm rods), and 50 mm ceramic wool insulation.

Microcomputer thyristor control type CO2 / MAG automatic welding machine Excellent workability & boasts robustness Ultimate new basic model