Fits your needs

OTC XD-600G

Description

Technical specification

by OTC Daihen

Ideal welding machine for thick plate work such as steel structure, bridge and shipbuilding 3 in 1 Micro-processor digital controlled multi-function welding machine, make welding more easy.

- Micro Processor Control

- Save Energy

- Four Type Welding Mode

- Co2 Welding

- MAG Welding

- DC Gouging

- DC Stick

Specification

| Welding Power Source | XD-600G | ||||||||||

| Rated Input Voltage | 220 V ± 10% | 380 V ± 10% | 415 V ± 10% | 440 V ± 10% | |||||||

| Rated Output Current | 600 A | ||||||||||

| Rated Load Voltage | 50 V | ||||||||||

| Output Current Range | 60 A – 600 A | ||||||||||

| Output Voltage Range | 15 V – 55 V | ||||||||||

| Max. no-load voltage | 84 V | ||||||||||

| Phase | 3 Phase | ||||||||||

| Frequency | 50/60 Hz | ||||||||||

| Rated Input | 47.7 kVA (36.6KW) | ||||||||||

| Rated Duty Cycle | 100% | ||||||||||

| Temperature Range | – 10℃ ~ + 40 ℃ | ||||||||||

| Dimensions (W x D x H) | 508 mm x 724 mm x 894 mm | ||||||||||

| Weight | 242 kg | 252 kg | 252 kg | 256 kg | |||||||

| Wire Feeder | CMXL-2301 | CMLW-231 | |||||||||

| Wire Size | 1.2, 1.4, (1.6) | (1.2), (1.4), 1.6, 2.0 | |||||||||

| Wire Type | Solid, Flux | ||||||||||

| Wire Feeder | Max. 18 m / min | ||||||||||

| Wire Reel | Shaft Dia. | 50 mm | |||||||||

| Outside Dia. | Max. 300 mm | ||||||||||

| Width | 103 mm | ||||||||||

| Wire Mass | Max. 25 kg | ||||||||||

| Mass | 10kg | 11kg | |||||||||

| Welding Cable | BKPT-7002 (2m) | ||||||||||

| Cable Diameter | 70mm² | ||||||||||

| Welding Torch | WT5000-SD | WTGUV-6001 | |||||||||

| Max Current | 500 A | 600 A | |||||||||

| Duty Cycle | 60% | 100% | |||||||||

| Wire Type | Solid, Flux | ||||||||||

| Wire Size ( mm ф ) | (1.2), 1.4, (1.6) | 1.6, 2.0 | |||||||||

| Mass (including cable) | 3.4 kg | 5.0 kg | |||||||||

Fitting your needs

PRODUCTS

is a state-of-the-art industrial robot designed to meet the demands of modern automation, Compact & high-performance

- Basic Function. Conduction of electricity with attaching tip. Supply of gas to nozzle. Specifications. Tip Body. Orifice – Baffle · Torch Body.

- Electric Insulation of nozzle (It is no problem if a nozzle touch on a base metal)

- It uniform the gas flow (laminar flow). It prevents short-circuit by spatter between noozle and tip body.

- MAG-tip has a further larger mass and largely-enhanced thermal capacity compared to T-tip.

- Standard Tip for CO2/MAG welding (normally-installed tip for Blue Torch Ⅱ)

Simple and excellent Durable structure … m Excellent operability as it is lightweight

Plasma welding machine Depending on the original torch structure Correspondent to stable and wide current range!

Ideal DC Arc welding machine with stable arc and less spatter by adopting high quality IC-Thyristor technology

- is ideal DC Arc welding machine with stable arc and less spatter by adopting high quality IC-Thyristor technology

High welding quality and high efficiency for mild steel, stainless steel,

nickel alloy with DC TIG, Pulsed DC TIG and DC Stick as standard modes.

New Compact Machine of D-series for multi purpose all materials such as steel, stainless steel and aluminum.

The Pinnacle of High-quality Thin Plate Welding Achieve highly efficient, high quality TIG-like bead appearances for MIG Applications

Further evolution of our high quality welding performance low spatter and low heat input CO2 /MAG welder

Welding Torch WT5000 S / M / L. Super ergonomic grip for easy operation

IGBT DC Converter Welding Machine

Using PCB, Small size, light weight, easy to carry

Adopting advanced electronic IGBT & reliable controlling circuit, stable current and good welding performance.

Thyristor control technology, with simple circuit and convenient maintenance.

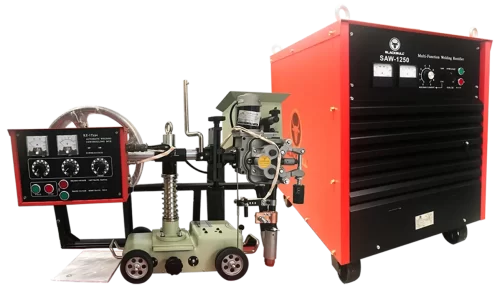

Suitable for SAW, and Carbon Gouging welding etc.

Microcomputer thyristor control type CO2 / MAG automatic welding machine Excellent workability & boasts robustness Ultimate new basic model

Synergic control One-Knob synergic control provides appropriate arc voltage for the welding current selected.