Fits your needs

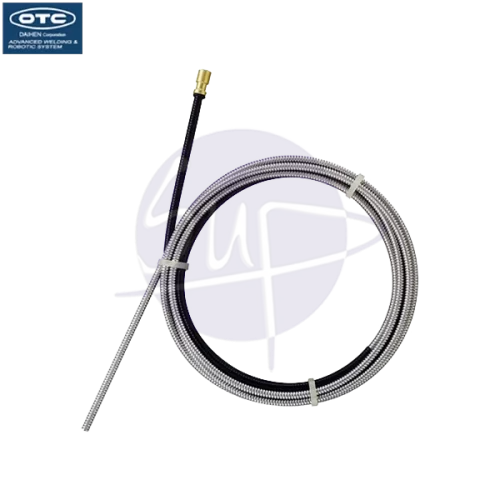

OTC TIP BODY

Description

Technical specification

OTC Daihen Contact Tip Holders for OTC MIG Torches

The OTC Tip Body, or contact tip holder, is an essential consumable in OTC Daihen MIG welding torches. Made from brass or heat-treated alloy, it securely mounts the contact tip, transmits welding current, and ensures proper shielding gas flow. Designed for durability and precision, these components are available in various models to match different torch series.

Used across manual and robotic welding systems, these tip bodies support wire sizes from 0.8 mm to 1.6 mm, depending on the application and torch configuration.

| Part Number | Torch Model(s) | Usage Type |

|---|---|---|

| U4170G03 | WT3500 | Standard incorporation |

| U4167G03 | WT3510 / WT3520 | Standard incorporation |

| U4173G21 | WT5000 | Standard incorporation |

| K5043C01 | WT2000F | Flexible correspondence |

| K4945C01 | WT3500F / WT3510F / WT3520F | Flexible correspondence |

| U2638H01 | WT3510 / WT3520 / WT5000 | For resist wind (outdoor) |

Main Features

-

- Precise Fit & Stability – OEM machined to fit Blue Torch II & WTCX torch bodies with minimal tolerance

- Gas & Electrical Conduction – Channels current and shielding gas effectively to the contact tip and weld zone

- Heat & Spatter Resistant – Designed for high-temperature durability and long operational life

- Multiple Part Numbers – Covers 2000F to 5000 series torches with standard or flexible fitting.

When to Replace the Tip Body?

-

- Worn or damaged threads

- Gas leakage

- Excessive heat discoloration

- Poor arc stability or wire misalignment

Replacing the tip body ensures safe torch performance, protects other consumables, and extends the torch’s lifespan.

The OTC Tip Body series (U4170G03, U4167G03, U4173G21, etc.) offers robust, high-conductivity solutions for various MIG torch setups—from manual WTCX to robotic Blue Torch II configurations. For best performance, match the correct part number with your torch model using the table above.

Need help finding a distributor or verifying compatibility with your welding setup? Just ask!

SHOP NOW

Discover more

4 kg payload collaborative welding cobot, 37 kg lightweight, ISO‑compliant safety, high trajectory accuracy—perfect for compact, flexible welding.

corded triple‑flange earplugs, washable, NRR 25 dB, stem insert design keeps tips clean and easy to fit.

Grade 9S Fine deburring wheel quickly removes burrs from metals & composites, delivering smooth, smear‑free finishes with long life.

is a high-strength SAW wire (EH14) ideal for carbon and low-alloy steels, offering high efficiency and low-temperature toughness.

Aluminum welding wire (2.4mm & 3.2mm) offers high strength and excellent corrosion resistance for TIG welding applications.

Digital air plasma cutter with powerful 60A output, suitable for cutting thick steel plates with precision and stability on-site.

Digital air plasma cutter with robust performance, ideal for on-site metal cutting tasks.

Digital AC/DC TIG welder with pulse control, ideal for aluminum, stainless, and mild steel.

AC/DC TIG welding machines with thyristor control, 7 welding modes, and up to 500A output, perfect for aluminum and various metal welding.

HANKIL 20m hose, 6.5mm diameter, grey color, lightweight and flexible. Ideal for medium-pressure industrial and agricultural applications.

500 A MAG/MIG synergic inverter welder, water‑cooled with trolley, 100% duty cycle—built for heavy-duty industrial welding operations.

FD‑V25 (S2) 6‑axis robot, 25 kg payload, 1.710 mm reach, slim design & fast cycle time—ideal for arc welding and material handling.

7-axis long-reach robot, 6 kg payload, 2 006 mm reach, ±0.08 mm repeatability—ideal for welding & handling in tight spaces.

is a 6‑axis industrial robot with 80 kg payload and 2.5 m reach, slim profile, built‑in cabling—perfect for material handling and welding support.

MIG/MAG inverter welder 30–400 A, DC/DC pulse & CBT‑EX low‑spatter mode, 400 V input, USB interface—built for steel, stainless & aluminum welding

PVC vinyl tape in black insulates electrical connections up to 600 V, resists abrasion and weathering, ideal for indoor/outdoor use, available in 8 colours.

PVC vinyl tape in white insulates electrical connections up to 600 V, resists abrasion and weathering, ideal for indoor/outdoor use, available in 8 colours.

Nozzle Cleaner: spray/gel nozzle treatment reduces spatter up to 80%, non‑toxic, silicone‑free, biodegradable & easy to apply.

Nozzle cleaner spray reduces spatter up to 80%, non‑toxic, silicone‑ & CFC‑free, biodegradable, easy spray-on application.

pickling gel removes heat tint and oxide from stainless steel, restores natural finish, multi‑position gel for easy use.

heavy‑duty anti‑spatter gel/spray reduces spatter by 80%, non‑toxic, non‑flammable, biodegradable, easy to apply.

Welding of 760MPa high tensile steel with outstanding mechanical properties (ASTM A514; A517; A710; JIS G 3128 SHY, HY-80, Q690 Grade).

For 560MPa tensile at LNG storage tank shipbuilding, bridges, good impact toughness at -60°C (Ni 1.5% contained).

For 490MPa high tensile steel and railcar, automotive, heavy equipment and general structural steel fabrications.

For 490MPa low temperature steel (NACE, API steel), Good impact toughness both AS-weld and PWHT conditions.

Welding of 22%Cr-12%Ni steel. Welding dissimilar steel such as joining Type 304 to carbon steel, welding the clad side of type 304 clad steel

Welding of ship hulls, high pressure vessels, heavy duty structures, bridges and general structural fabrication

Welding of aluminium-killed steel used at low temperature, LPG tankers and LPG storage tanks etc.

Flat and horizontal fillet welding of ship structures, bridges and general structural steels.

Welding of 490MPa class high tensile steel of ships, buildings and high resistance to crack.

Welding of 490MPa class high tensile steel of ships, buildings and high resistance to crack.

Welding of aluminium-killed steel used at low temperature, LPG tankers and LPG storage tanks, pipe etc.

Ceramic insulators for 350 A & 500 A OTC MIG torches. Ensure proper shielding gas flow, tip alignment, and electrical isolation.

350 A ceramic gas diffuser, ensures smooth laminar gas flow and prevents arc spatter at tip—durable precision for tight welding.

OTC Long‑Tip contact tip: .030–.062″ MIG tip, 45 mm long M6 thread, ideal for narrow grooves and deep access—durable and precision‑machined.

MAG-tip has a further larger mass and largely-enhanced thermal capacity compared to T-tip.

Standard Tip for CO2/MAG welding (normally-installed tip for Blue Torch Ⅱ)

6-axis arc welding robot with 2.008m reach and 6kg payload, perfect for precise welding in confined spaces.

Plasma welding machine with 0.5–300A current range and high efficiency, perfect for precision welding on steel and stainless steel.

Plasma cutting machine with 120A current and up to 60mm cutting capacity, perfect for precise cutting of thick metal plates.

DC welding machine with digital control and IC-Thyristor technology, up to 400A current, perfect for precise welding on various metal types.

DC welding machine with IGBT inverter control, up to 400A current, ideal for welding with cellulose-coated electrodes in all positions.

AC/DC TIG welding machines with thyristor control, 7 welding modes, and up to 300A output, perfect for aluminum and various metal welding.

Digital inverter TIG welding machine with automatic synergy function, up to 300A current, compact design, ideal for mild steel, stainless steel, and nickel alloys.

AC/DC TIG welding machine with hybrid AC+DC mode, up to 350A current, AC frequency up to 500Hz, perfect for aluminum and thin to thick steel plates.

Compact CO₂/MAG/MIG welding machine with up to 210A output, ideal for light industry and automotive repair applications.

Versatile CO₂/MAG welding machine with up to 600A output, ideal for steel structures, bridges, and shipbuilding.

Digital inverter welding machine with up to 400A output, ideal for automated and robotic applications across various materials.

Digital inverter welding machine with up to 300A output, ideal for MIG/MAG and TIG applications across various materials.

Digital inverter welding machine with up to 300A output, ideal for MIG/MAG and TIG welding across various materials.

Digital inverter CO₂/MAG welders up to 500A, featuring stainless steel mode and storage for 30 welding conditions for high efficiency.

350A/500A digital inverter welders with optimal current control, high arc stability, and low spatter for high-quality welding results.

350A digital inverter welder featuring low spatter mode, optimal current control, and high arc stability for superior welding quality.

500A digital inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

400A AC/DC inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

400A digital inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

500A CO₂/MAG welding torch featuring ergonomic design, air cooling, and flexible cable for precise welding and maximum comfort.

13-inch welding glove offering heat protection and comfort, ideal for TIG and MIG applications.

Solid MIG wire ER70S-6 offering stable arc performance, ideal for carbon & low-alloy steels, compatible with CO₂ or mixed shielding gases.

1.2mm flux-cored welding wire, ER70S-6 class, ideal for welding carbon and low-alloy steels with CO₂ or mixed shielding gas.

Microcomputer thyristor control type CO2 / MAG automatic welding machine Excellent workability & boasts robustness Ultimate new basic model

Synergic control One-Knob synergic control provides appropriate arc voltage for the welding current selected.

a cutting-edge digital inverter CO₂/MAG welding machine offering precision control, low spatter, and high efficiency for industrial applications.