Fits your needs

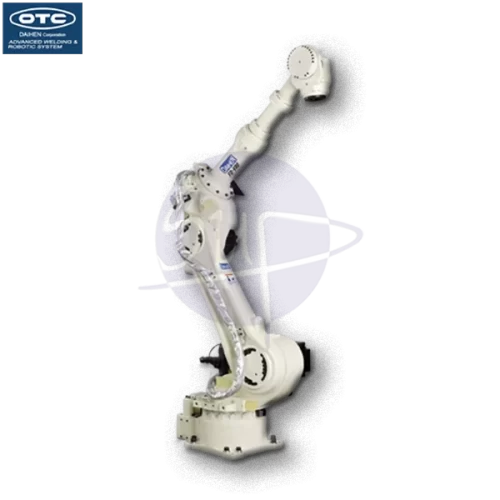

OTC ACCUTIG 500P

Description

Technical specification

OTC ACCUTIG 500P – High-Performance AC/DC Pulsed TIG Welding Machine for Industrial Applications in Batam

The OTC ACCUTIG 500P is a high-quality AC/DC pulsed TIG welding machine designed for maximum precision, power, and reliability. Engineered with advanced thyristor control technology, this machine delivers a stable arc with minimal spatter—ideal for producing superior welds across a variety of metals, including aluminum and stainless steel.

Perfectly suited for the industrial needs of Batam, this model offers unmatched flexibility with seven welding modes, high current output, and a 100% duty cycle for continuous operation.

Key Features:

-

- Thyristor Control Technology: Ensures stable arc and reduces spatter, enhancing weld quality.

- Seven Welding Modes: Provides flexibility for various welding applications:

- DC Pulsed TIG

- DC Stick

- Rectangular Wave AC Pulsed TIG

- Rectangular Wave AC Stick

- DC TIG

- TIG Arc Spot

- Rectangular Wave AC TIG

- High Output Current: ACCUTIG 500P delivers up to 500A, accommodating various welding requirements.

- 100% Duty Cycle:Enables prolonged welding operations without overheating, enhancing productivity.

- User-Friendly Design: Features intuitive controls and robust construction for reliable performance in demanding environments.

| Specification | ACCUTIG 500P |

|---|---|

| Power Supply | Single-phase 380/400V |

| Rated Output | 500A |

| Output Adjustment Range | AC/DC: 10–500A |

| Duty Cycle> | >100% |

| Dimensions (W x D x H) | 508 x 724 x 895 mm |

| Weight | 273 kg |

| Welding Torch | AW-12 |

| Cable Hose | BMRH-5001 |

Applications in Batam’s Industrial Sector:

The OTC ACCUTIG 500P are ideal for:

-

- Aluminum Welding: Ideal for automotive, shipyard, and aerospace fabrication in Batam.

- Stainless Steel Fabrication: For creating durable and clean welds in heavy-duty environments.

- Precision Welding Tasks: Suitable for electronics and medical equipment manufacturing requiring fine control.

Advantages:

-

- Enhanced Productivity:High output current and 100% duty cycle enable continuous welding operations.

- Versatility: Adaptable across multiple industrial applications in Batam and beyond.

- Durability: Robust construction ensures reliable performance in demanding work environments.

- Safety: Incorporates multiple protection features to safeguard both the operator and the equipment.

Whether you’re working in metal fabrication, shipbuilding, or precision component manufacturing in Batam, the OTC ACCUTIG 500P is a powerful and reliable choice for professional TIG welding.

Discover more

The LORCH X 350 PST is a robust MMA welding system with automatic polarity switching, ControlPro digital interface, and MicorBoost technology—ideal for tough construction and pipeline jobs.

LORCH X 350 – compact 350 A MMA welder with MicorBoost, vertical TIG capabilities (ContacTIG/MicorUp), and rugged IP34S build. Ideal for mobile industrial welders in Batam.

Lorch V 50 AC/DC – 500 A heavy-duty TIG welder with pulse up to 20 kHz, SmartBase controls, and robust housing — ideal for shipyards and fabrication in Batam.

Lorch V40 AC/DC TIG welder blends 400 A heavy-duty welding with pulse up to 20 kHz, SmartBase control, and robust housing—ideal for shipyards and fabrication in Batam.

LORCH MicorMIG Mobile 350 – pulse arc welding with MicorBoost reduces spatter and rework. Upgradeable, reliable, and efficient—ideal for fabrication, shipbuilding, and workshop use in Batam.

LORCH MicorMIG Mobile 300 – low‑spatter pulse arc welding with MicorBoost & NFC upgrades. Ideal for Batam’s fabrication, shipbuilding, and workshop welding.

Lorch MicorMIG Pulse 500 – high-power, low-spatter MIG/MAG pulse welding with MicorBoost, EN 1090 compliance & NFC upgradeability. Ideal for Batam’s heavy industry.

Lorch MicorMIG Pulse 400 – high-performance MIG/MAG pulse welding with MicorBoost, EN 1090 compliance, and NFC upgradability. Ideal for shipbuilding, fabrication, and workshop applications in Batam.

Lorch MicorMIG Pulse 350 – pulse arc welding with MicorBoost reduces spatter and rework. Upgradeable, reliable, and efficient—ideal for fabrication, shipbuilding, and workshop use in Batam.

Lorch MicorMIG Pulse 300 – low‑spatter pulse arc welding with MicorBoost & NFC upgrades. Ideal for Batam’s fabrication, shipbuilding, and workshop welding.

Lorch MicorMIG 500 – Top-tier MIG/MAG welder for industrial-grade projects in Batam, with German MicorBoost technology and full-process capability.

Lorch MicorMIG 350 – Premium German-made MIG/MAG welder with MicorBoost and SpeedArc, ideal for industrial welding in Batam’s fabrication and shipbuilding sectors.

Lorch MicorMIG 400 – High-power industrial MIG/MAG welder with MicorBoost and SpeedArc, ideal for fabrication, shipbuilding, and manufacturing in Batam.

Lorch MicorMIG 300 – German-engineered MIG/MAG welder with MicorBoost technology, perfect for industrial applications and mobile welding jobs in Batam.

The Lorch S8 SpeedPulse XT offers high-performance MIG/MAG welding with advanced SpeedPulse technology, ideal for shipbuilding and industrial welding in Batam.

The Lorch S5 SpeedPulse XT delivers top-tier MIG/MAG pulse welding with intelligent arc control—ideal for heavy-duty fabrication and shipyard welding in Batam.

4 kg payload collaborative welding cobot, 37 kg lightweight, ISO‑compliant safety, high trajectory accuracy—perfect for compact, flexible welding.

Digital air plasma cutter with powerful 60A output, suitable for cutting thick steel plates with precision and stability on-site.

Digital air plasma cutter with robust performance, ideal for on-site metal cutting tasks.

Digital AC/DC TIG welder with pulse control, ideal for aluminum, stainless, and mild steel.

Ensures precise tungsten electrode grip for stable arc performance in WP17/18/26 TIG torches.

Carbon gouging rods deliver precise metal removal with excellent arc stability for heavy-duty applications.

500 A MAG/MIG synergic inverter welder, water‑cooled with trolley, 100% duty cycle—built for heavy-duty industrial welding operations.

FD‑V25 (S2) 6‑axis robot, 25 kg payload, 1.710 mm reach, slim design & fast cycle time—ideal for arc welding and material handling.

7-axis long-reach robot, 6 kg payload, 2 006 mm reach, ±0.08 mm repeatability—ideal for welding & handling in tight spaces.

is a 6‑axis industrial robot with 80 kg payload and 2.5 m reach, slim profile, built‑in cabling—perfect for material handling and welding support.

MIG/MAG inverter welder 30–400 A, DC/DC pulse & CBT‑EX low‑spatter mode, 400 V input, USB interface—built for steel, stainless & aluminum welding

OEM contact tip holders for OTC MIG torches (WT2000–5000), ensures secure electrical flow & precise wire feeding.

Ceramic insulators for 350 A & 500 A OTC MIG torches. Ensure proper shielding gas flow, tip alignment, and electrical isolation.

350 A ceramic gas diffuser, ensures smooth laminar gas flow and prevents arc spatter at tip—durable precision for tight welding.

MAG-tip has a further larger mass and largely-enhanced thermal capacity compared to T-tip.

Standard Tip for CO2/MAG welding (normally-installed tip for Blue Torch Ⅱ)

Simple and excellent Durable structure … m Excellent operability as it is lightweight

6-axis arc welding robot with 2.008m reach and 6kg payload, perfect for precise welding in confined spaces.

6-axis arc welding robot with extended reach and 8kg payload, perfect for precise welding on large components.

Plasma cutting machine with 120A current and up to 60mm cutting capacity, perfect for precise cutting of thick metal plates.

DC welding machine with digital control, up to 630A current, and gouging function, ideal for welding low-carbon steel to copper alloys.

DC welding machine with digital control and IC-Thyristor technology, up to 400A current, perfect for precise welding on various metal types.

DC welding machine with IGBT inverter control, up to 400A current, ideal for welding with cellulose-coated electrodes in all positions.

AC/DC TIG welding machines with thyristor control, 7 welding modes, and up to 300A output, perfect for aluminum and various metal welding.

DC TIG welding machine with pulsed TIG and Stick modes, up to 315A current, perfect for mild steel, stainless steel, and nickel alloys.

Digital inverter TIG welding machine with automatic synergy function, up to 300A current, compact design, ideal for mild steel, stainless steel, and nickel alloys.

AC/DC TIG welding machine with hybrid AC+DC mode, up to 350A current, AC frequency up to 500Hz, perfect for aluminum and thin to thick steel plates.

Compact CO₂/MAG/MIG welding machine with up to 210A output, ideal for light industry and automotive repair applications.

Digital inverter welding machine with up to 400A output, ideal for automated and robotic applications across various materials.

Digital inverter welding machine with up to 300A output, ideal for MIG/MAG and TIG applications across various materials.

Digital inverter welding machine with up to 300A output, ideal for MIG/MAG and TIG welding across various materials.

350A digital inverter welder with low spatter and low heat input technology, ideal for thin plate welding and industrial automation.

Digital inverter CO₂/MAG welders up to 500A, featuring stainless steel mode and storage for 30 welding conditions for high efficiency.

Digital inverter welders with electronic reactor control, delivering high-quality welds with minimal spatter and optimal arc stability.

350A/500A digital inverter welders with optimal current control, high arc stability, and low spatter for high-quality welding results.

350A digital inverter welder featuring low spatter mode, optimal current control, and high arc stability for superior welding quality.

500A digital inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

400A AC/DC inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

400A digital inverter welder featuring pulse mode, optimal current control, and high arc stability for superior welding quality.

500A MIG welder featuring double pulse technology, ideal for precise welding of aluminum, steel, and various metals.

300A inverter TIG welder featuring IGBT technology, compact design, high efficiency, and precise control for quality welds

120A inverter welder, lightweight and portable, ideal for DIY projects and light industrial applications with high efficiency.

Microcomputer thyristor control type CO2 / MAG automatic welding machine Excellent workability & boasts robustness Ultimate new basic model

Synergic control One-Knob synergic control provides appropriate arc voltage for the welding current selected.

a cutting-edge digital inverter CO₂/MAG welding machine offering precision control, low spatter, and high efficiency for industrial applications.